Thomas Lojek

Interview with

Itai Nakash:

SAN Tactical

Electro-Hydraulic Breaching

Hydraulic breaching has become a core capability for many special operations and tactical law enforcement units operating in complex urban environments.

In this interview, Itai Nakash of SAN Tactical explains how electro-hydraulic breaching evolved from operational necessity, how it is deployed alongside other breaching methods, and why mindset and training remain as critical as the tools themselves.

The discussion focuses on real-world decision-making, risk management, and capability development within special operations contexts.

Why Hydraulic Breaching Matters in Tactical Operations

Thomas Lojek: Why should law enforcement agencies and special operations units consider SAN Tactical breaching tools today?

What operational problem do they solve better than existing alternatives?

Itai Nakash: When we talk about existing alternatives, I’m referring to other methods of entry based on our operational experience and testing—methods such as explosive, exothermic, mechanical, and similar approaches.

Today, and for the past 15 years, the primary method of entry we use in Israel has been hydraulic tools.

We took a close look at what was available and realized that special operations units cannot rely on tools that were originally designed for firefighters or rescue teams.

Those tools were never intended for tactical operations.

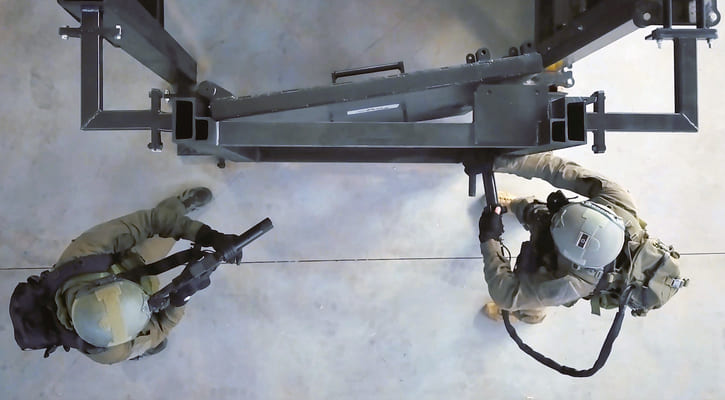

We needed to design something specifically for law enforcement and military operators—especially special operations units that require very fast entry, and often the ability to conduct low-signature or near-silent entry.

Another key requirement was adaptability.

Operators need a tool that can be carried with them and adjusted to different urban environments without having to bring multiple systems or heavy equipment.

That led us to a design based on a backpack-mounted system, where most of the weight sits on the operator’s back.

The operator then holds only the end tool in hand.

Instead of carrying a 15-kilogram tool, a generator, or other heavy equipment, our main tools typically weigh between four and five kilograms.

This setup allows operators to deal with a wide range of obstacles commonly found in urban environments—push doors, pull doors, zero-gap doors, rolling and sliding doors, as well as ship doors, train doors, aircraft doors, standard vehicles, and even armored vehicles.

With the SAN Door Breaker, which is our primary tool, these obstacles can be overcome very quickly.

The way we approached the design—drawing directly from our military background—resulted in a system that operators are comfortable using and confident carrying throughout their missions.

Operational Endurance: How Many Breaches One Operator Can Sustain

Thomas Lojek: How many doors or objects can you breach with the SAN Door Breaker during a mission?

Itai Nakash: At a minimum, around 25 doors.

With our Flex capability, which was released in 2024, combined with the advanced control box and a DeWalt battery powering the unit, that number increases to around 35 doors.

If an operator deploys with two batteries, it’s possible to reach 50 to even 70 breaches during a mission.

And I’m not talking about very light doors—I’m referring to Class 3 doors, breached repeatedly.

That means a single operator can handle a significant number of breaches during one mission without needing to change systems or bring additional equipment.

When Electro-Hydraulic Breaching Is the Preferred Option

Thomas Lojek: Can you explain a scenario where electro-hydraulic breaching is the preferred option?

Itai Nakash: I can give you several scenarios, but let’s start with a hostage situation or a terror attack:

Normally, in the first minutes of an operation—and sometimes even for the first few hours—you don’t always know what kind of doors you’re going to encounter.

In many cases, you also need to breach multiple doors during the same mission.

Today, at least in Israel, the common approach in these specific scenarios is to have an explosive breacher on one entry point and a hydraulic breacher on another.

Whichever entry is achieved fastest becomes the point of entry for the team.

The problem is that when you use explosives—especially in a hostage situation—a lot of things can go wrong.

You can injure hostages inside, create collateral damage that delays entry, or turn the breach into something that is no longer clean.

There is also an increased risk to your own team.

With hydraulic breaching, you significantly reduce those risks.

Even if the first attempt is not perfect, you can reverse, reposition, and apply the tool again.

With explosives, if the breach is not effective, that’s it.

Re-setting explosives takes time and exposes the team further, often under compromised conditions.

In most missions, you also don’t want to wake up the entire neighborhood—especially in a hostile urban environment.

Mechanical and explosive breaching methods generate a lot of noise and attention.

Sometimes the element of surprise is better achieved by going in fast and quiet.

Explosives can provide shock effect, and that is a valid option in some scenarios, but the operational reality for many units is different.

The objective is often to go in, detain the wanted individual, and get out without creating unnecessary disruption.

Think about drug labs, for example.

There are many things that can go wrong.

These are explosive environments, and using explosive breaching there can be extremely dangerous.

The same applies to gas leaks or rescue scenarios—situations where even firefighters cannot use tools that might create a spark.

If we’re talking about lower liability and reduced risk for the operator, hydraulics offer a safer option.

In environments involving chemicals, gas, or volatile substances, an explosive breach can potentially destroy the entire building.

Hydraulic breaching avoids that risk.

There is also the long-term impact on operators.

Brain injuries associated with repeated explosive exposure are widely discussed within the operator community.

By using hydraulic breaching, you can reduce that exposure and help keep operators safer and healthier over the long term.

Operator Feedback: Mindset, Learning, and Reality

Thomas Lojek: What kind of feedback have you received from operators after their first real deployment that still surprises you?

Itai Nakash: I would divide the feedback into two categories, because there is a clear difference between operators who go through the full capability implementation with us—including training—and those who do not.

The feedback from operators who fully engage is very strong, and we’re proud of that.

SAN systems are operationally deployed in 45 countries worldwide, and we maintain close relationships with master breachers in many of those units.

What stands out is that they don’t just listen to us explain the capability—they understand it once they actually put the tool in their hands.

Very often the reaction is something like:

“I can’t believe this.

I’ve spent my entire career working on doors for ten minutes or more, and now I can breach the same door in under ten seconds.”

That shift is significant.

It changes the operator’s mindset, and that’s something we’re proud to see.

The second category is more challenging.

There are also end users who believe they already know everything.

Ego exists everywhere.

Some operators don’t show up with the intention to learn, and that can create friction.

Hydraulic breaching is different, and if you don’t have the proper background, you won’t use it correctly.

If someone approaches it with the mindset that they are already a master breacher in all disciplines, the experience can become frustrating.

The tool might be positioned incorrectly, the technique might be wrong, or the door may not have been properly analyzed before starting.

In those cases, the problem isn’t the system—it’s how it’s being used.

That’s the key difference for me: operators who want to learn, not just purchase equipment, versus those who believe they already have all the answers.

Sometimes those same users will say, “Your system didn’t breach the door in under ten seconds,” or “I broke something.”

My response is always the same: come to the course.

Regardless of what happened, attend the three-day basic course, and I can guarantee that afterward, you’ll understand what you’re doing.

Good training, an open mindset, and attention to detail are essential in special operations—and that applies directly to breaching.

It’s not just about having the tool.

Mindset and training are just as critical.

A breacher needs to be trained by breachers who have real operational experience.

Breachers train breachers.

That’s how you become mission-ready.

Training Thresholds: When a Breacher Is Mission-Ready

Thomas Lojek: When it comes to training, how much training is actually enough before an operator can be trusted with a system in a real operational environment?

Itai Nakash: One of the things we often hear from operators coming from the explosive breaching background is: “Okay, I know—I’ll need weeks of training, and I’ll need to repeat it many times before I’m qualified as an explosive breacher.”

Our answer is: in order to be qualified as a hydraulic breacher, you need three days.

Yes, it’s an intense course, but in three days we can build the capability for a breacher to be confident enough to approach a door and conduct a breach in a real-life operation.

It doesn’t take that long to become an effective breacher with our tools.

If the unit also has our training aids, they can continue to train internally—again and again—on the methods and techniques taught during the course.

That repetition reinforces confidence and competence.

Of course, there are advanced breaching modules—for night operations, hard targets, underground environments, and similar scenarios—that we provide specifically for special operations units.

But the baseline breacher skill level is achieved in those three days.

After that, operators know how to use the tools properly in an operational context, and they feel confident approaching doors in hostile environments.

One Core System, Different Operational Environments

Thomas Lojek: You work with different branches of the operator community—military, special operations, SWAT, and firefighters.

How do you categorize these deployment environments, and how do you adapt your training, configurations, and products for each category?

Itai Nakash: On the training side, the first thing to understand is that we use different instructors with different operational backgrounds for each type of unit.

I cannot teach firefighters the same techniques, or understand their operational reality, if I don’t come from that background myself.

Their missions are different, and the way firefighters approach an operation is very different from how military or law enforcement units operate.

That said, the core principle of our system—the electro-hydraulic power unit—is the same across all environments.

Whether it’s military, law enforcement, firefighters, or rescue units, the underlying system remains identical.

Where the differences come in is at the tool and configuration level.

The door breaker itself is always the same and remains the primary tool for all users.

But beyond that, we offer different types of spreaders, cutters, and backpack configurations to match the mission profile.

For example, special operations units usually ask for a very compact tool and a compact backpack, optimized for mobility and integration with other equipment.

Firefighters and rescue personnel, on the other hand, typically don’t carry the system on their back in the same way, because they often already have oxygen tanks or other gear mounted there.

When we started the company, our focus was clearly on tactical operations.

That’s our root and our heritage.

Over time, firefighters and rescue units began adopting our tools for specific scenarios within their own mission environments.

But the original idea—the core principle of SAN Tactical—was developed for tactical operations.

That’s where we come from, that’s where our strongest expertise is, and that remains the primary focus guiding our future designs.