Thomas Lojek

Interview

Christian Peagler

and

Joe Perry:

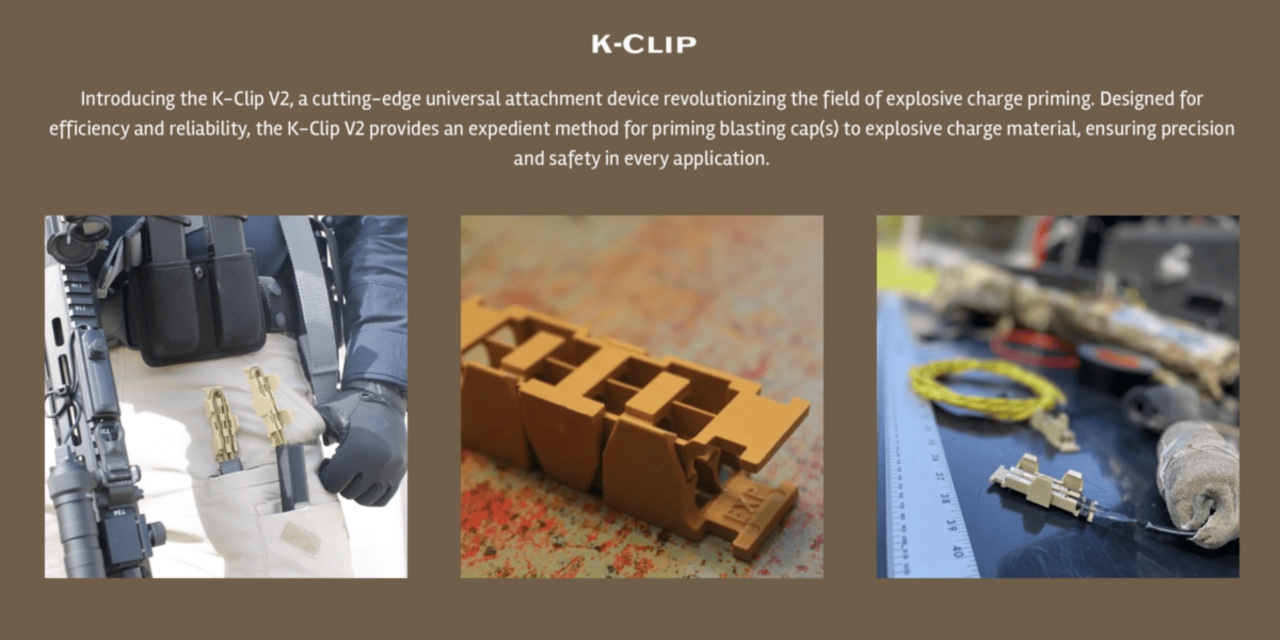

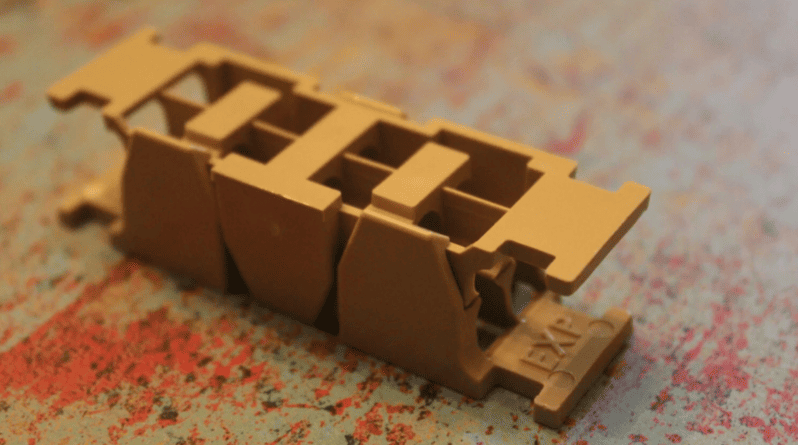

K-Factor Breaching K-Clip V2

Operational Speed, Safety, and Versatility

Christian Peagler’s journey to Chief Operations Officer of K-Factor Breaching and co-creator of the K-Clip began in the private armed security sector, continued with his service in the United States Marine Corps as a Combat Engineer, and carried over into law enforcement in East TN.

Throughout his extensive career in the Marine Corps and Law Enforcement he has trained others in various combat and law enforcement scenarios in the areas of patrol tactics, casualty care, advanced breaching tactics, and defense tactics.

Joe Perry’s began his journey to Chief Executive Officer of K-Factor Breaching and a co-creator of the K-clip instructing at his family’s shooting range at a young age.

He later served in the United States Marine Corps as a Combat Engineer in Afghanistan.

During his time in service he accumulated extensive experience in mobility operations, counter I.E.D. warfare, and urban breaching.

He later transitioned into Law Enforcement where he served in the roles of Patrol Deputy, SWAT team member, and General Investigator.

Joe Perry brings his expertise in breaching charges and tactics to the team and is dedicated to safety, security, and excellence in all his endeavors.

The Origin of the K-Factor Breaching K-Clip

Thomas Lojek: What is the story behind the K-Factor Breaching K-Clip?

Christian Peagler: Over the years, we noticed a crucial need for increased speed and safety in tactical operations.

During our own experience as operators, we observed the serious consequences of inadequate safety measures.

This is not a minor issue—it regularly leads to serious injuries during breaching operations.

Recognizing the urgency of the problem, we began developing ideas for a product that prioritizes speed while also ensuring operator safety.

What the K-Factor Breaching K-Clip Does

Thomas Lojek: What does the K-Factor Breaching K-Clip do?

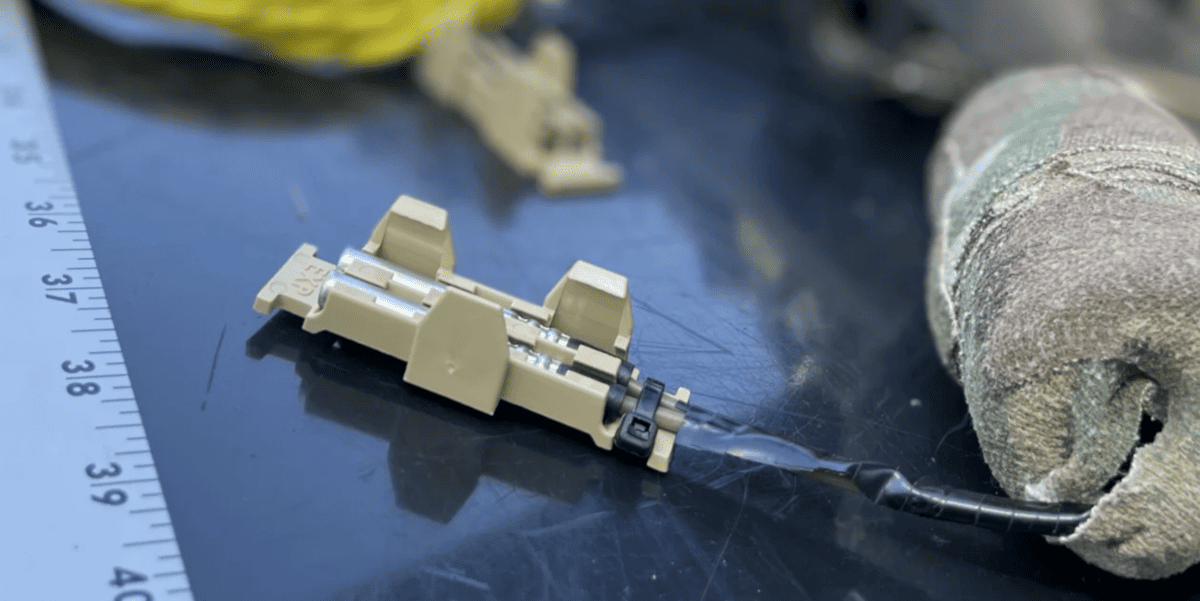

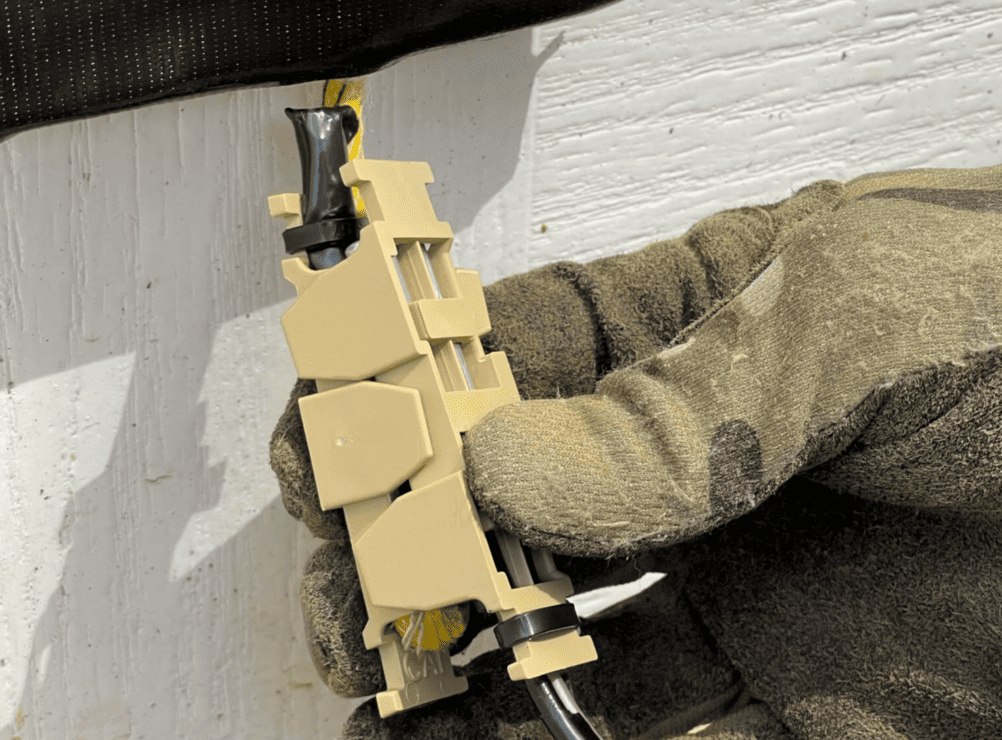

Joe Perry: The K-Clip V2 is a universal attachment device for explosive charge priming.

It provides an expedient method for attaching blasting cap(s) to explosive charge material, ensuring precision and safety in every application.

In practical terms, the K-Clip V2 is a versatile attachment device that seamlessly connects blasting caps to explosive charge material.

Its universal design makes it suitable for a wide range of applications.

Whether you’re operating in special operations, law enforcement, first response, rescue teams, or in demolitions, mining, or any application that requires precise explosive charge priming, the K-Clip V2 functions as a safe, easy-to-use, and incredibly fast attachment device in any scenario.

Engineered with safety as a priority, the K-Clip V2 is designed to facilitate complete deflagration of the explosive charge material and priming clip.

This ensures a controlled and thorough combustion process that meets the highest safety standards.

It also means that no additional fragmentation material is introduced into the charge, unlike some of the bulkier QCC systems currently in use.

Small Tool, Significant Operational Impact

Thomas Lojek: Interesting.

Small tool, huge impact, so to speak.

Christian Peagler: Absolutely.

Another important point is cost efficiency.

The K-Clip reduces the costs associated with replacing components in traditional two-part systems.

It’s a small change with a significant impact, especially considering that budgets are tight across almost all sectors.

Design Decisions Behind the K-Clip V2

Thomas Lojek: Tell me more about the design decisions that ultimately shaped the form and function of the K-Clip.

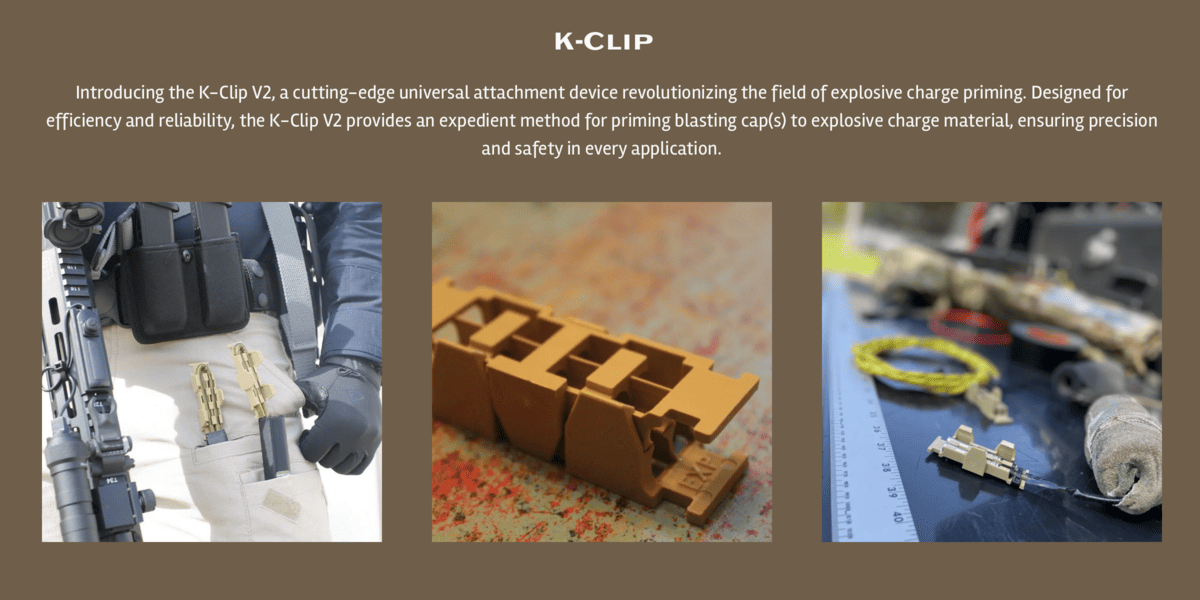

Joe Perry: From the beginning, it was essential that the system work in low-light and no-light conditions.

The coloration of the K-Clip V2 was specifically chosen to support these environments, improving visibility and usability where lighting is limited.

This also makes it easier to use while operating with NODs or NVDs.

The K-Clip V2 is manufactured from waterproof materials, which was another critical requirement.

This ensures reliable performance in all environmental conditions, including wet or challenging settings—which are often the reality in operational environments.

Another key point was eliminating the need for additional adhesives.

The K-Clip V2 removes the requirement for extra bonding agents, simplifying the priming process and improving efficiency and ease of use.

The clips snap together securely, creating a strong connection point that can still be quickly disconnected without dealing with adhesive removal.

Finally, every K-Clip V2 is identical, which is essential for a truly universal replacement option.

Seamless interchangeability and the elimination of multiple specialized clip types streamline maintenance and operations.

Once again, it comes down to time, safety, and speed—small but critical details that ultimately enhance an operator’s ability to do his job.